Introduction:

Actuators are devices, which produce movement that can be controlled precisely. Ceramic micro-actuators are far superior compared to conventional actuators such as stepper motors or solenoids. piezoceramic based actuators offer the most cost effective, longer life solution that show repeatable results. To meet diverse applications that demand unique combination of performance parameters such as displacement, force, response time, input voltage and size, a variety of piezoactuator designs are adopted.

PIEZO ACTUATOR DESIGNS

The piezoelectric designs that have been realized at C-MET Thrissur are, bulk piezoactuators, Unimorph, Bimorph, Multilayer piezoceramic actuators, Multilayer electrostrictive actuators, Flextensional actuators and twin amplified actuators. Salient features of some of the piezo designs realized are,

Multilayer (ML) Piezoceramic & Electrostictive actuators

For applications that demand maximum force, minimum voltage and fast response ML actuators are exploited. Typical parameters are,

- MAX. FORCE (3000 – 10000 N)

- DISPLACEMENT: 2 to 10 µ

- LOW VOLTAGE (100-150 V)

- BEST RESPONSE TIME (0.1 ms)

- HIGH ELECTROMECHANICAL COUPLING k33 (70%)

- LIFE TIME HIGH (1011 CYCLES)

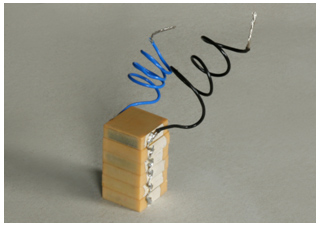

ML Stack Actuator

For applications that demand increased displacement with all other parameters same as ML actuator, ML stack actuators are used.

Bimorph actuators

For applications that demand maximum displacement and minimum force, Bimorph actuators/benders are used.

- FORCE - A few N

- DISPLACEMENT – 10 to 2000 µ

- RESPONSE TIME (10 ms)

- ELECTROMECHANICAL COUPLING k33 (10%)

- LIFE TIME MODERATE (108 CYCLES)

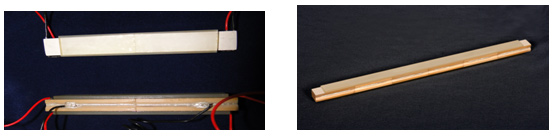

Bimorph Mirrors

For precise & reproducible control of radii of curvature for the focusing of X-rays Bimorph based piezoelectric mirrors are exploited.

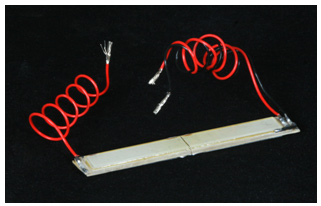

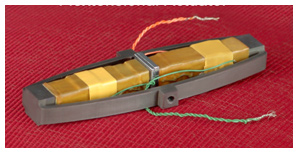

Flextensional Actuator

For applications that demand amplified displacement and reasonable force Flextensional/Twin amplified actuators are used.

- FORCE (20 – 1200 N)

- LOW VOLTAGE (100-150 V)

- DISPLACEMENT: 25 – 1000 µ

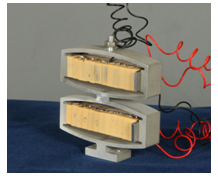

Twin amplified Actuator

- FORCE (20 – 1200 N)

- LOW VOLTAGE (100-150 V)

- DISPLACEMENT: Twice that of Flextensional Actuator

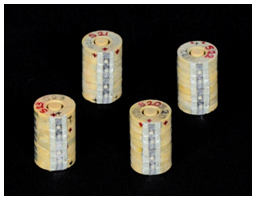

ML Ring Actuators

ML ring actuators were also realized for specific strategic application. ML ring actuator of specific dimensions can be realized depending on the application.

- LOW VOLTAGE (70-150 V)

- STRAIN: 0.1 %

Applications

In general, various applications for piezoactuators include, Precise positioning, X,Y stage, XYZ and Theta precise control, microvalve, micro pump, injection system, vibration and noise suppression, linear and ultrasonic motors etc. Some of the major fields of application are given in table below.

|

Field |

Applications

|

|

Mechanical engineering |

Positioning of tools, clamps, active wedges, Damping Active control, Generation of ultrasonic or sonic vibrations.

|

|

Microelectronics |

Positioning of masks, wafers or magnetic heads, Non-magnetic actuation, Micro-relay.

|

|

Fluids |

Proportional valves, Pumps, Measuring, Injections, Ink jet, Droplet generators

|

|

Optics |

Positioning of mirrors or lenses, Focusing, Laser cavity tuning, Alignment or deformation of fibers, Scanners, Choppers, Interferometers, Modulators

|

|

Electrical engineering |

Fast circuit breakers, Electrical power generators from mechanical energy

|

|

Automobile |

Common Rail Diesel Injection (CRDi), Multi point fuel injection (MPFi).

|

Other major fields of application include Underwater Sonar, Biomedical, Defence, Space and MEMS.

Future Possibilities

Multilayer benders, Piezo transformers and other piezo actuator designs.

II. MATERIALS FOR ELECTRONIC PACKAGING APPLICATION

Glass + ceramic Low temperature (900 oC) co-fired ceramic (LTCC) composition has been developed. The developed composition meets all requirements for LTCC application. The picture below shows the LTCC tapes developed at C-MET, Thrissur.

Currently work is being carried out on ultra low temperature (u-LTCC) compositions. The development of thick film Ag and Al based compositions for co-firing with LTCC/u-LTCC is under progress.